Views: 0 Author: Site Editor Publish Time: 2025-01-10 Origin: Site

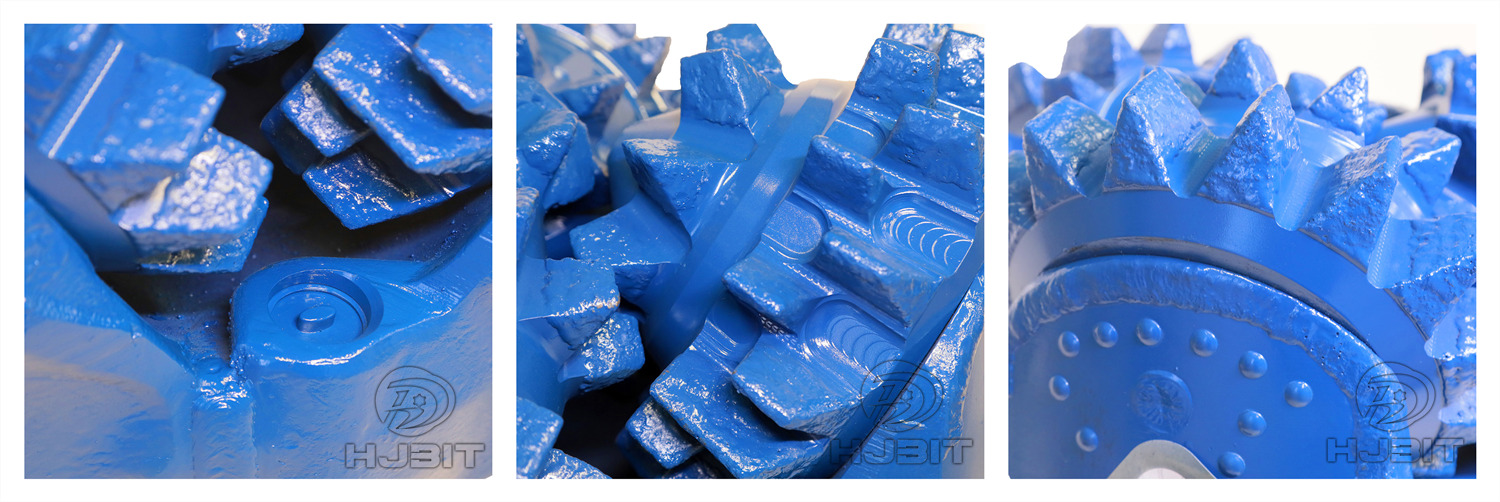

A PDC (Polycrystalline Diamond Compact) bit is a cutting-edge tool used in drilling operations to penetrate rock formations efficiently. Unlike traditional bits, PDC drill bits are designed with synthetic diamond cutters that offer superior durability and cutting performance. These bits are widely employed in various industries, including oil and gas exploration, geothermal drilling, and horizontal directional drilling (HDD).

At Hejian Hengji Bit Manufacture Co., Ltd., we specialize in the production of high-quality PDC bits and related drilling tools. With over 15 years of experience and advanced manufacturing capabilities, our products are trusted by clients in over 40 countries to deliver exceptional results in demanding drilling projects.

PDC drill bits have revolutionized the drilling industry by providing enhanced penetration rates and extended lifespan. Their unique design ensures better energy transfer to the drilling surface, resulting in faster and more efficient operations. When paired with tools like the PDC Hole Opener, these bits further elevate the efficiency of drilling projects by enabling smooth and consistent hole enlargement processes.

Weight on Bit (WOB) is a critical factor influencing drilling performance. It refers to the amount of downward force exerted on the drill bit during operation. Proper WOB is essential for achieving optimal performance with PDC drill bits and PDC Hole Openers.

Impact of WOB on PDC Bits: Excessive WOB can lead to bit wear and damage, reducing its lifespan. Insufficient WOB, on the other hand, can cause inefficient cutting and slow drilling progress. A balanced WOB ensures that the PDC drill bit performs effectively without undue stress.

Optimizing WOB for PDC Hole Openers: When using a PDC horizontal directional drilling hole opener, maintaining the correct WOB ensures efficient hole enlargement while minimizing tool wear. Operators often rely on advanced monitoring systems to measure and adjust WOB in real-time.

At Hejian Hengji, our advanced CNC machines and professional engineering team enable us to deliver customized solutions tailored to specific WOB requirements for different formations.

| Formation Type | Recommended WOB (lbs) |

|---|---|

| Soft formations | 5,000 - 10,000 |

| Medium formations | 10,000 - 20,000 |

| Hard formations | 20,000+ |

Rotary speed, measured in revolutions per minute (RPM), is another key parameter affecting drilling efficiency. The interaction between rotary speed and WOB directly influences the performance of both PDC drill bits and hole opener drill bits.

Optimal Rotary Speed: Higher rotary speeds enhance cutting efficiency in softer formations but may cause overheating and wear in harder materials. Lower speeds, combined with higher WOB, are often preferred for tough formations to ensure steady cutting.

Rotary Speed for PDC Hole Openers: Using a customized hole opener requires precise speed adjustments to match formation conditions. This ensures smooth operation and extends the tool's service life.

With state-of-the-art equipment and a professional design team, Hejian Hengji ensures that our PDC tools, including hole openers, are engineered for optimal performance across varying rotary speed requirements.

| Tool Type | Formation Type | RPM Range |

| PDC drill bit | Soft | 150-250 |

| PDC Hole Opener | Medium | 100-200 |

| Metal hole opener | Hard | 50-100 |

Formation hardness and composition significantly impact the choice and performance of drilling tools. Understanding these factors is vital for optimizing the use of PDC Hole Openers and related equipment.

Soft Formations: Tools like hole opener bits excel in soft formations due to their ability to maintain high rotary speeds and rapid penetration rates. These formations require minimal torque and energy, making PDC Hole Openers an ideal choice.

Medium Formations: Medium-hard formations demand a balance between cutting speed and durability. Hole opener bit suppliers often recommend PDC tools for their adaptability to such conditions.

Hard Formations: In hard and abrasive formations, the durability of the PDC material is crucial. Metal hole openers and reinforced PDC tools are often employed to withstand extreme conditions while maintaining efficiency.

At Hejian Hengji, our commitment to innovation ensures that our products are built to perform effectively in all formation types, providing customers with durable and high-performing tools.

| Formation Type | Recommended Tool | Key Features |

| Soft (e.g., clay) | PDC Hole Opener | High penetration rates |

| Medium (e.g., limestone) | PDC horizontal directional drilling hole opener | Balance of durability and speed |

| Hard (e.g., granite) | Metal Hole Opener | High durability and torque |

Q1: What is a PDC Hole Opener?

A1:A PDC Hole Opener is a specialized tool used to enlarge drilled holes in various formations. It features durable PDC cutters designed to provide efficient hole expansion while minimizing tool wear. These tools are widely used in HDD, mining, and geothermal projects.

Q2: How Does a PDC Hole Opener Improve Drilling Performance?

A2:The PDC Hole Opener enhances drilling performance by:

Reducing overall operational time.

Providing smooth and consistent hole enlargement.

Extending the lifespan of drilling equipment.

Q3: Where Can I Find Reliable Hole Opener Bit Suppliers?

A3:Reputable hole opener bit supplier offers a wide range of products, including customized hole openers and standard tools. These suppliers ensure high-quality manufacturing and provide tools suited to specific project needs.At Hejian Hengji, we pride ourselves on being a trusted supplier of high-performance PDC tools, meeting the needs of clients worldwide.

Q4: Are There Hole Openers for Sale That Cater to Unique Requirements?

A4:Yes, many manufacturers provide customized hole openers to meet unique project requirements. These tools are tailored to match specific formation conditions, ensuring optimal performance and durability.

Q5: Why Choose a Metal Hole Opener for Hard Formations?

A5:Metal hole openers are designed to withstand the high stress and torque associated with drilling through hard formations. Their robust construction ensures long-lasting performance and minimal downtime.

PDC Hole Openers are indispensable tools for modern drilling operations. Their ability to enhance drilling performance, coupled with their adaptability to various formations, makes them a preferred choice for industries ranging from oil and gas to HDD and mining. By understanding factors such as WOB, rotary speed, and formation composition, operators can maximize the efficiency and lifespan of these tools. Whether sourced from trusted hole opener bit suppliers or designed as customized hole openers, PDC tools represent the forefront of drilling technology.

At Hejian Hengji Bit Manufacture Co., Ltd., our mission is to provide innovative, high-quality drilling solutions tailored to meet the evolving demands of the industry. For your next project, explore the wide range of hole openers for sale and invest in tools that guarantee superior performance and reliability.